RUCO PRODUCTS, INC.

We take pride in our facility and most visitors’ first reaction is “WOW, you can eat off the floor!”

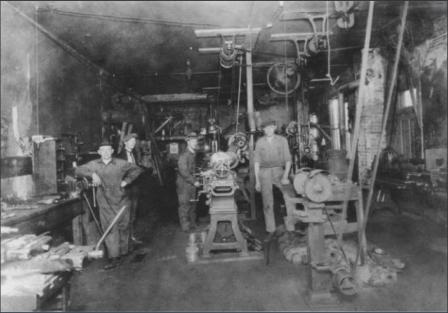

The journey of the family businesses started in 1918 as Rupert Machine Works and was founded by Richard “Dick” Rupert (1886 - 1985). The business was located in Kansas City, Missouri and primarily produced repair and maintenance parts for oil pipeline pumps.

Ruco Products, Inc. 2620 SW US Highway 40 Blue Springs, MO 64015

Custom Plastic Injection Molding

By 1940 a new manufacturing technology in plastic resins was just emerging; Plastic Injection Molding. In 1941 Dick transitioned the diecast business into a plastic injection molding business. Some of the key items produced were an injection molded casing for proximity fuses that was sold to the US military during WWII and also one on the first plastic squeeze bottles ever made.

After the war, in 1947 Dick changed the name of the business to Rupert Manufacturing Company and moved it to 1229 Montgall in Kansas City, Missouri. The proliferation of injection molded products during the 1950’s and early 1960’s aided Rupert Manufacturing in growth for the next seventeen years. During this time Mr. Rupert spun off a couple of satelite businesses like the Stratoliter Company which specialized in quality injection molded and assembled cigarette lighters. He also developed and patented one of the original designs for reflector lenses. The product line was named Stratolite and was immensely successful. In 1956 the company was moved to Blue Springs, Missouri where it continued to grow and prosper

Richard “ Dick” Rupert 1886-1985

In 1930 Dick opened the Rupert Die Casting Company that specialzed in aluminum diecast products such as the “juicer”. The “juicer” was a common household implement for juicing oranges, grapefruit and lemons. I’m sure most of us remember seeing one of these used by grandma.

Rupert Machine Works - 1918

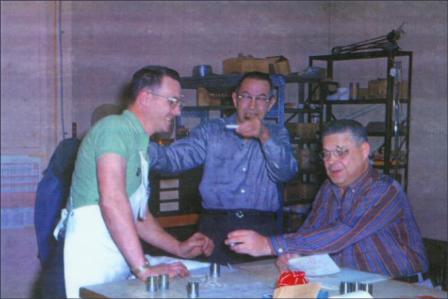

Dick (center) with employees at Rupert Manufactuirng Company

Stratolite reflector lens.

Rupert Manufacturing Company

The First Generation

The Second Generation

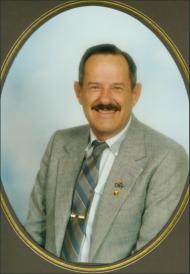

R.D. “Corky” Rupert

In 1965 Dick’s son, R. D. “Corky” Rupert started his own enterprise. The Tor-Shell Company located at 11th and Main in Blue Springs, Missouri, specialized in plastic injection molded guitar pics of all shapes and sizes.

In 1964 Dick sold the Rupert Manufacturing Company along with all patents for Stratolite.

Ruco Products, Inc. 2620 W 40 Highway, Blue Springs, MO - 1967

Ruco’s first “big machine” was a Van Dorn 200 ton. Since that day Ruco has added 13 machines and has expanded the facility five times. Ruco established a “full service” machine shop, where many molds were designed, machined and assembled for production. The 200 Ton Van Dorn is still used ocassionally for production duties.

Today much of the work is perfomed by modern, computer controlled 300 Ton Van Dorn machines. Process controls are more consistant as well as is the quality of the final product.

Original building from the northwest and from the southwest.

In 1967 a building became available that was located between the east and west bound lanes of US 40 Highway in Blue Springs, Missouri. The building was originally used for a Recreational Vehicle sales/service facility and was a perfect fit for a small injection molding enterprise. Corky purchased the building and Ruco Products, Inc was formed. Ruco has remained at the same address since.

Delivery of the 200 Ton Van Dorn

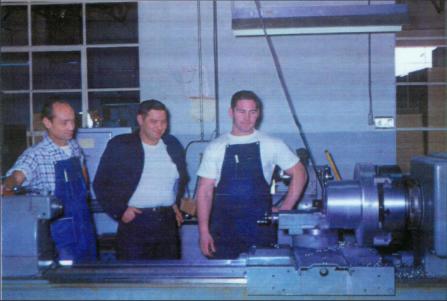

Gale Howard working the lathe during the 1960’s

Although retired, both Corky and Gale still make a daily presense at the plant. Gale is often consulted for his machining expertise.

Gale in the Tool Room, 2008

The Third Generation

Brenda “Bea” Rupert, 2008

Brenda started working at Ruco part time as a teen. Her duties often included mundane tasks such as mold polishing and floor scraping. So to say Brenda started at the bottom and worked her way up would be very accurate.

After spending a few years working as the personal assistant to the President of the Bank of Jacomo, Brenda started full time at Ruco in 1977. For the next 17 years Brenda learned every aspect of the injection molding business. In 1995 Brenda took over the reins and became President of Ruco Products, Inc. In 2014 Ruco became

officially certified as a Missouri Woman Business Enterprise (WBE); and the first WBE

Plastic Injection Molder in Missouri.

officially certified as a Missouri Woman Business Enterprise (WBE); and the first WBE

Plastic Injection Molder in Missouri.

Brenda put her stamp on the business when she negotiated a deal with Teledyne/Isco out of Lincoln, Nebraska to do custom injection molding and a separate specialized manufacturing process for one of their major product lines. This business alone nearly doubled the annual sales of Ruco and for eight years was a very successful side addition to the Ruco injection molding manufacturing process.

Redisep Associates 2007

Columns for Teledyne/Isco

Under Brenda the latest additon to the facility was the West wing which was added in 1995. The addition currently houses both finished good and raw material inventory’s.

During the 1970’s, one of Ruco’s first large customer accounts was Intec medical that specialized in inhalation therapy equipment. Ruco and Intec grew significantly out the mutually beneficial relationship.

As can be observed in the photo album section of this site, Brenda has successfully struck a balance between success and promoting a fun family atmoshere. She takes great pride in long term relationships from retiring our first machine operator after 25 years to management positions exceeding 50 years of service.

Ruco specialized in everyday products that many people have used or at least seen in their life. For example Ruco made literally millions of Sun Tea lids and also produced the plastic cases for the security tags that department stores would clip to their mechandise. Many products were also produced for the medical and animal veterinary supply industry and continue to be a major part of Ruco’s business to this day.

Gale Howard was instrumental and very active in the R&D, Engineering and Prototyping of customer molds and products. His innovation led the way for Ruco to be successful in quickly bringing many concepts to reality.

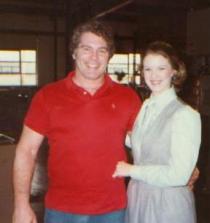

Gale Howard & Brenda, 1983

Two management associates that have been instrumental in the success of Ruco over the last two decades are Derek Kirkpatrick, Vice President and Ed Robinson, Plant Manager. Derek joined Ruco in 1984 and worked his way up through the ranks to his current position. His knowledge of the injection molding process as well as other aspects of the molding business make him a valuable asset on Brenda’s staff. Ed was our contract electronic typewriter repairman that Brenda felt was of very high character and in 1995 made Ed an employment offer he couldn’t refuse. Ed’s people handling skills and dedication to the business have made a huge impact on the overall success of Ruco.

left to right, Mark Bossert, Ed Robinson and Derek Kirkpatrick. 2008

Brenda spends much of her time at the Ruco East facilty and leaves much of the details of daily duties to her staff.

Brenda has a pet project (literally) that she has been working on for the last several years. Her dedication to rescuing wayward animals has brought several as permanent additions to the Ruco home.

Corkie in his office, 1968

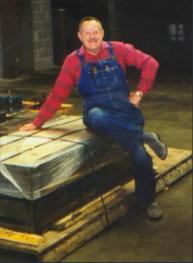

Corky in the new warehouse.